Hala Sultan Tekke is an important Islamic site near Larnaka, as well as being close to a Salt Lake, and a major Late Bronze Age settlement. As part of the ongoing study of material excavated from that settlement in the late 20th century by the Swedish archaeologist Paul Åström, we are investigating selected finds of metallurgical debris, such as slag, crucible fragments, and tuyères.

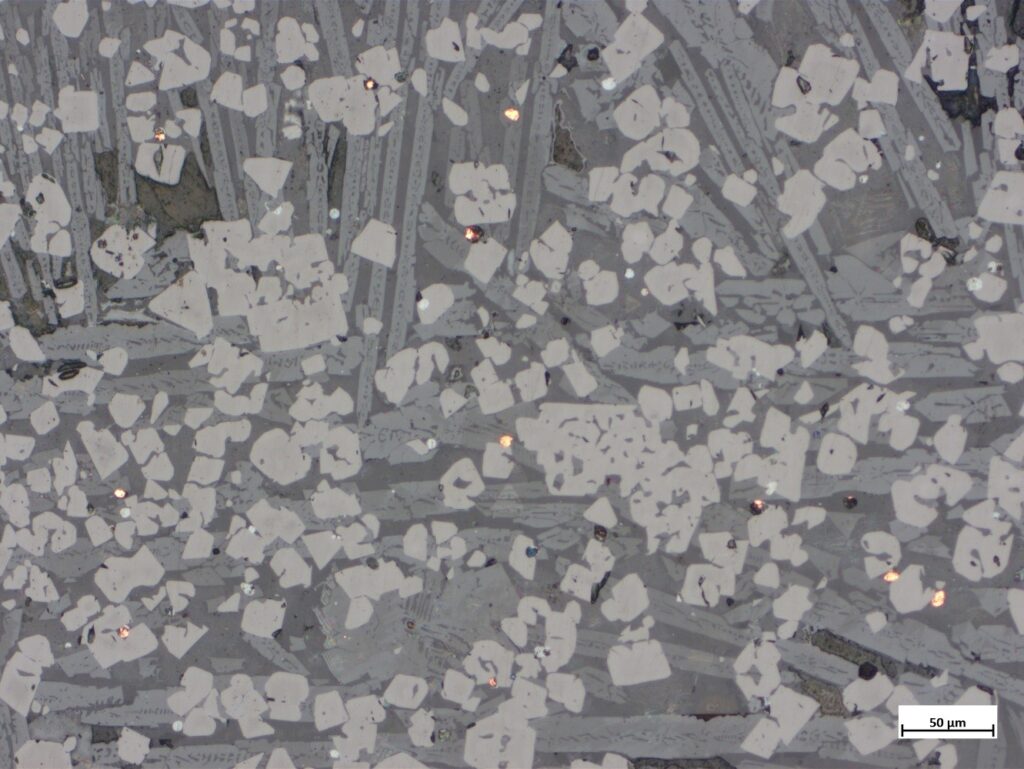

The presence of large quantities of slag in the Bronze Age city is unusual, as one would not expect copper smelting to take place in a densely populated area. However, the analyses confirm that these slag fragments result from copper smelting, using an ore rich in chalcopyrite. Most of the slag is fayalite (long mid-grey needles), with magnetite crystals (light grey) forming from the iron content of the chalcopyrite. Small droplets of either copper sulfide, known as matte, or copper metal are present in all samples. This is a very typical feature of prehistoric copper smelting slags, worldwide.

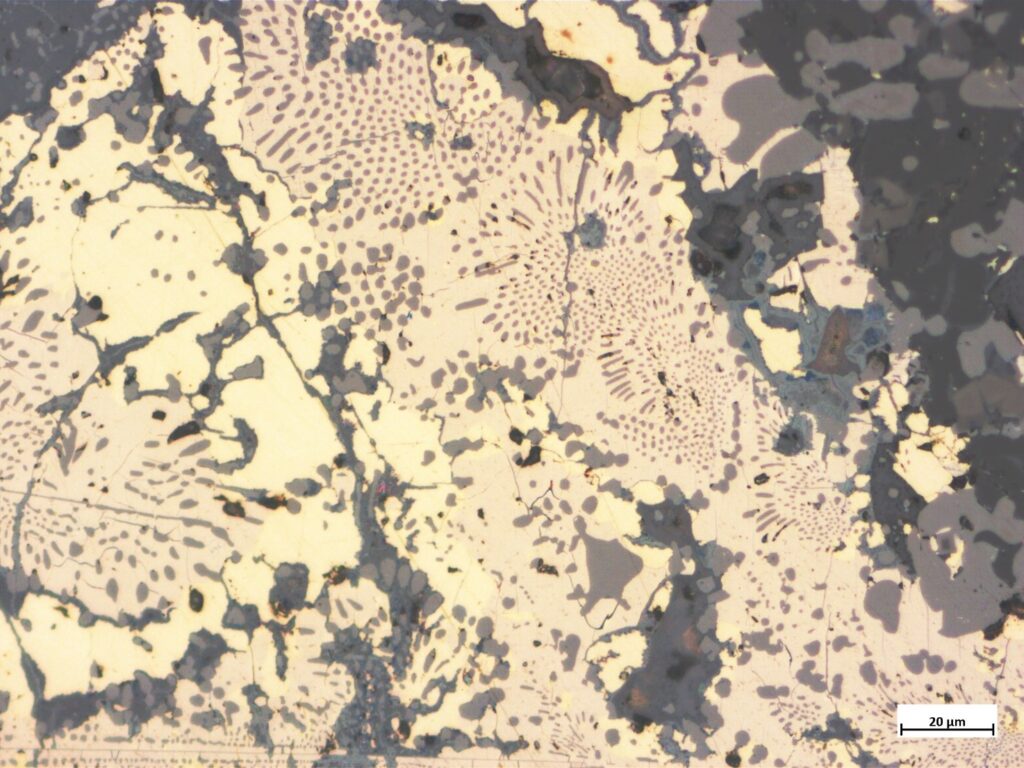

Some of the slag pieces preserve the detail of the chemical reaction taking place in the furnaces. The picture below shows the reduction of chalcopyrite (CuFeS2) to copper-rich matte and iron oxide. Here, the yellow chalcopyrite can change into a more brown bornite (Cu5FeS4) and magnetite (Fe3O4) in a characteristic eutectic form, as more or less elongated round dark grey particles. If this piece of slag had stayed in the furnace a little longer, then all of the iron and sulfur from the ore would have been oxidized, leaving behind only pure copper and a slag rich in iron oxide.

The crucible fragments and tuyères demonstrate that the metal workers at Hala Sultan Tekke were also processing bronze, the copper-tin alloy. Ongoing research aims to link the two technologies. One possibility is that the copper smelted on site was alloyed with tin to make bronze. This could explain why there is copper smelting slag in the settlement, when during the Late Bronze Age most copper smelting took place at dedicated smelting sites in the mountains, near the sources of ore and fuel.

The tuyères work together with crucibles to blow sufficient air into the charcoal in the crucibles to melt the copper or bronze, which can then be cast into moulds to make various objects. The crucibles fuse on their inside under the intense heat, with the normally red ceramic body turning into a black layer where it gets in contact with charcoal and molten metal.